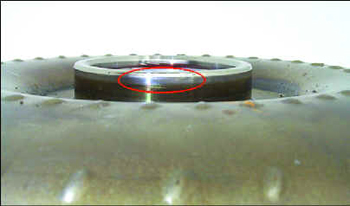

One of the more frustrating comeback problems with the G4A-EL is a front seal leak. The usual causes of this are either insufficient contact between the seal lip and the torque converter hub, or the seal moving out of position in the stator support. There is now an aftermarket seal available that solves both of these problems (figure 1). The solution is in the overall height of the seal.

Figure 1

The additional wall height of the seal provides greater wall contact with the stator support bore, making the seal much less likely to move after installation. That, coupled with using a high quality hardening sealer, should assure positive bore position of the seal.

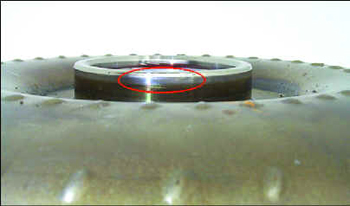

Our test converter hub shows the contact point between the converter hub and an OE seal lip installed in typical fashion (figure 2). This contact point is very near the end of the hub, and in operation the hub may pull partially out of the seal, causing a substantial front leak.

Figure 2

The height of the taller replacement seal doesn't permit installing the seal too deep into the stator support, assuring proper positioning of the seal lip on the converter hub.

Since seal installation depth is a critical issue on this unit, there is a special factory tool used for installing this seal. However, there is an acceptable method for installing this seal without the use of special tools. All you need is a 4T60 (440T4) second clutch drum and a hydraulic or arbor press. Here's how:

Step 1: Place the drum upside-down on the bed of the press.

Step 2: Coat the outside diameter of the seal with a quality hardening sealer and place it upside-down on the center of the clutch drum (figure 3).

Figure 3

Step 3: Holding the stator support upside-down, place it on top of the seal (figure 4).

Figure 4

Step 4: Press the support squarely down over the seal until the support contacts the clutch drum (figure 5).

Figure 5

This procedure will locate the seal properly within the stator support, where it will line up as it should with the torque converter hub. It will also remain locked into the support without moving out of position in operation. This installation procedure also avoids accidentally deforming the seal by misplaced hammer blows, which can also cause leaks (figure 6).

Figure 6

Consult your parts supplier to determine if this taller replacement seal is available to you and avoid the headaches of front seal leaks on this unit.