The Chrysler 41TE has had a recurring problem with broken overdrive/underdrive pressure plate snap rings. Over the years, Chrysler has made many attempts to correct this problem:

These modifications have created a parts interchange nightmare, the most common of which includes using a pressure plate/snap ring/drum combination that allows the pressure plate to move up and down between the plate snap rings.

OD/UD pressure plate movement between the snap rings can cause several operating problems that can't be programmed or adjusted out of the unit. Keep in mind, the shift feel control system is almost entirely operated by the transmission controller, which responds to the time it takes for the shift to happen. Changes in turbine and output shaft speed provide the information for these calculations. One thing that will affect the time it takes for the shifts to occur is clearance, or how far something has to move to work. If the pressure plate can move between the snap rings, it adds a whole new dimension to what you believe your clutch clearances to be.

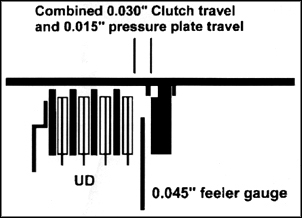

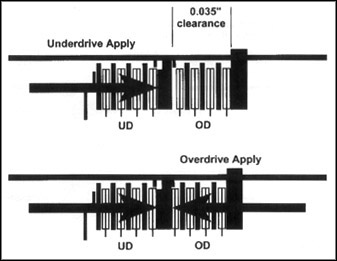

Let's say you assemble a drum that has 0.015" pressure plate movement. When you check your underdrive clutch clearance, the pressure plate will move up and add its movement to what you think the clearance is. You may observe 0.045" clearance, which is okay. But 0.015" of that movement is pressure plate travel, resulting in a real clutch clearance of 0.030" -- which is just too tight (figure 1).

Figure 1

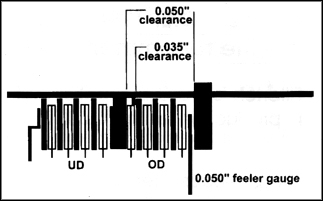

When you check overdrive clutch clearance, the pressure plate is down against the bottom snap ring. If the observed clutch clearance is 0.050" with the pressure plate down, there's really only 0.035" clearance when the pressure plate pushes up against the top snap ring; far too tight for proper operation (figure 2).

Figure 2

When the shifter is placed in OD at a stop, the UD clutch applies for 1st gear. This takes up both the UD clearance of 0.030" and the pressure plate travel of 0.015". Since piston travel is the full 0.045", the unit engages normally.

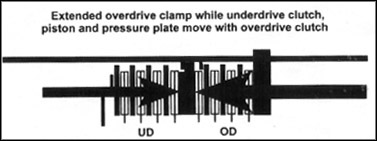

But on the 2-3 shift, the OD clutch applies. Since the pressure plate is against the top snap ring, the OD clutch clearance is too tight, bringing the OD clutch on too quickly (figure 3). The shift overlaps too much, resulting in a harsh or binding 2-3 shift and low OD clutch CVI numbers from your scanner. Unfortunately, this part of the problem isn't over yet.

Figure 3

The OD piston apply surface is greater than the UD clutch piston, by about two square inches. This means that before the OD piston can really clamp the OD clutch against the OD/UD pressure plate, it must first push the pressure plate, the UD clutch pack and the UD clutch piston down until the pressure plate hits the bottom snap ring (figure 4). This allows the OD clutch to slip on final apply, scorching the plates and causing early clutch failure. But wait, there's more!

Figure 4

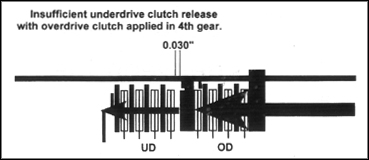

During a 3-4 shift, the OD clutch remains applied. Meanwhile, the UD clutch must release and the 2-4 clutch must apply in a timed, orderly fashion. But the UD/OD pressure plate is now against the bottom snap ring, bringing UD clearance down to the initial 0.030" clutch travel. The clutch won't release as quickly or completely as it should, resulting in a dragging or binding 3-4 shift feel (figure 5). Hold on, we're not through with this yet.

Figure 5

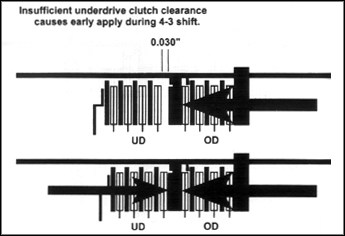

During a 4-3 shift, the OD clutch remains applied. The 2-4 clutch must release while the UD clutch applies, once again, in a timed, orderly fashion. Can you predict what happens instead? Since the UD clutch clearance is much tighter than it should be, it pops right on earlier than it should, before the 2-4 clutch has had a chance to start releasing (figure 6). You guessed it: a dragging or binding feel to the 4-3 downshift, possibly scorching the UD and 2-4 plates. And scorched 2-4 clutch plates aren't going to help the 1-2 shift quality much, are they?

Figure 6

It's painfully clear why this pressure plate motion must not exist for the unit to work properly. So how do you avoid it during a rebuild? Keeping all the parts updates in mind, and building the unit with only the proper combinations will keep these problems from surfacing. But remember how this article started?

The root problem is broken snap rings!

Now what do you do? Deal with the whole mess in one fell swoop. If you disassemble a unit that hasn't been worked on before, and the parts discussed here are in good shape, don't change any of them. Keep them all together and you'll be okay.

But if you need to change the drum, pressure plate or snap rings, or you have one of the problems listed above and no apparent cause for the problem, throw away the drum, pressure plate and both snap rings. The last change to these parts, listed at the beginning of this article, has resulted in a kit you can buy from the dealer. It includes the input drum, both snap rings (of the latest thickness) which don't break, and two OD/UD pressure plates of different thickness. These plates are two of the four that were previously available to adjust UD clutch clearance. Chrysler has determined, of the four plates available, these are the two most commonly used plates, so they give you both of them in the kit.

This reasonably priced kit is available under Chrysler part number 4886300AA (figure 7).

Figure 7

Avoid the aggravation, delays, and customer anxiety caused by the problems listed above by getting one of these kits in stock today. You'll be glad you did the next time you run across the old 604 busted snap ring trick!

![]()