|

|

Chapter 3

GM's 4L80E: 1991-92

|

Transmission Overview

Based on the old 400 transmission, the 4L80E combines heavy duty capacity with electronic accuracy and control. The two shift solenoids receive power whenever the key is on. The computer supplies ground to the solenoids to energize them.

The converter clutch solenoid receives a pulse width modulated signal, to provide smooth converter clutch operation.

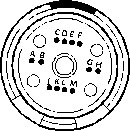

Terminal Identification

Here’s a breakdown of the individual connector terminals:

Shown from the terminal side of the transmission connectors.

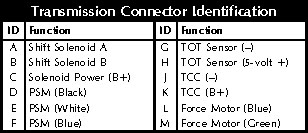

Electronic Pressure Control

To check the electronic pressure control signal, connect your high-impedance voltmeter or signal monitor to the terminals shown.

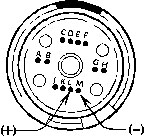

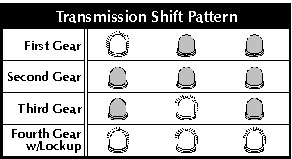

Checking the Shift Pattern

Here’s how to connect your signal box to the transaxle connector, to check the signals from the computer to the transaxle:

Backprobe the terminals with the harness

connector still connected to the transmission.

This is the shift pattern you should see with your signal monitor:

The far right LED indicates the signal to the converter clutch (TCC) solenoid.

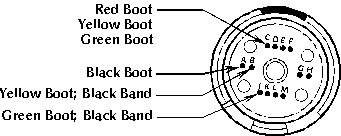

Forcing the Shift

Here’s the manual shift pattern you can expect with the transmission in failsafe:

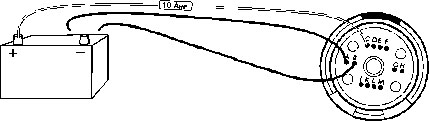

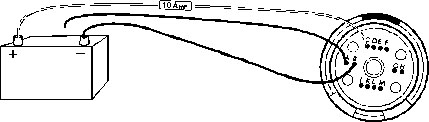

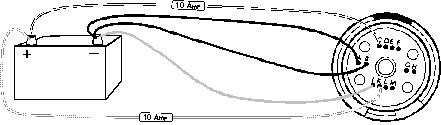

And here’s how to force the 4L80E to shift electrically:

First Gear

In first gear, only solenoid A receives ground.

Second Gear

To shift into second gear, the computer releases ground from solenoid A; neither solenoid is grounded.

Third Gear

To shift into third gear, the computer only grounds solenoid B.

Fourth Gear

To shift into fourth gear, the computer grounds both shift solenoids; the gray lines are the connections necessary to apply the converter clutch.

Never leave the TCC applied for more than a few seconds. Any longer could burn out the solenoid.

Never leave the TCC applied for more than a few seconds. Any longer could burn out the solenoid.

PAGE 44-45

![]() Never leave the TCC applied for more than a few seconds. Any longer could burn out the solenoid.

Never leave the TCC applied for more than a few seconds. Any longer could burn out the solenoid.